Fall Factors

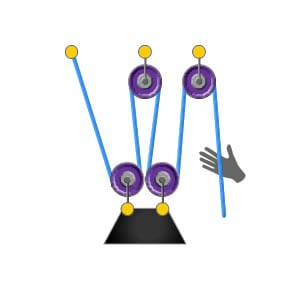

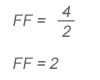

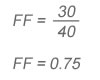

Calculating a fall factor is achieved by simply taking the distance of the fall and then dividing it by the length of rope or lanyard available to absorb the energy;

![]()

While a fall factor does identify the possible loadings that will be exerted on both the climber and the equipment, even a low fall factor could have fatal consequences. Big falls can still result in low fall factors where attention should be made towards the amount of distance fallen and the necessary clearance required.

This page uses diagrams and references to testing standards to assist in the understanding of fall factors, these have been included purely for illustrative purposes only! In no way do they suggest a recommendation or represent how the equipment should or could be used.

Fall Factor Chart

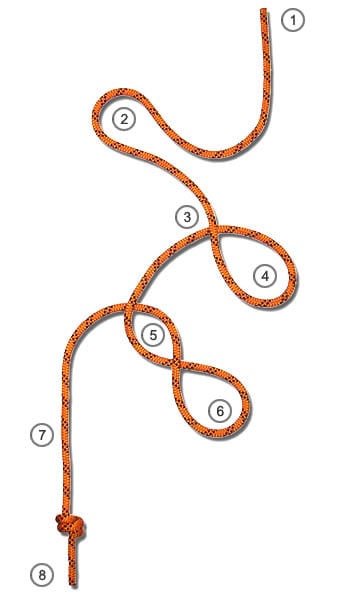

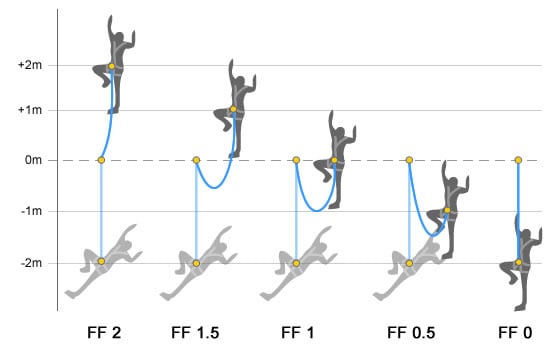

The chart below displays several examples of different fall factors. All the lanyards are made from a two metre length of dynamic rope which has been clipped to a fixed anchor point.

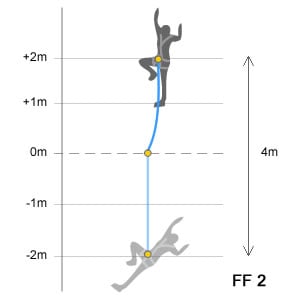

Fall Factor Two - FF2

In this situation the climber has a lanyard made from a section of dynamic rope that is two metres in length which is connected to a fixed anchor point. The climber has climbed two metres past the anchor point and can no longer climb any further.

If the climber were to fall from this point then he or she would fall two metres (2m) to the anchor point and then an additional two metres (2m) past the anchor point (the length of the rope or lanyard).

Overall the climber would fall a total distance of four metres (4m) until the fall is arrested by the rope. Using the equation above to work out the fall factor;

Normally we should not be able to achieve a fall factor greater than two (FF2). A fall factor two or FF2 could potentially exert a significant amount of force both on the climber and the equipment in the system, this will also include the anchor point! Dynamic climbing ropes certified to the European EN 892 standard are tested to withstand only a certain number of fall factor 1.77 falls prior to failure occurring.

It is bad practice to accept a fall factor two in any situation. Fall factors should be kept as minimal as possible to reduce the likelihood of excessive forces being applied to the climber and the equipment.

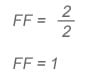

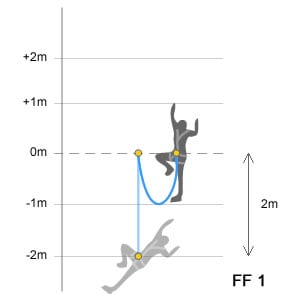

Fall Factor One - FF1

In this diagram the climber has a two metre dynamic rope lanyard that is connected to an anchor point. The anchor point is at the same height in relation to the harness attachment point, meaning that the climber could fall a distance of two metres. So;

This would result in a fall factor one (FF1). Low-stretch or semi-static ropes conforming to the European EN 1891 standard are tested to hold a specific number of fall factor one (FF1) falls before failure occurs. Although using semi-static rope to arrest falls should always be avoided as significant and possibly fatal forces can be exerted on the climber, the anchor point and the equipment.

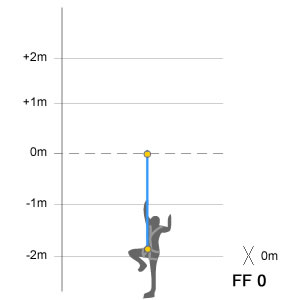

Fall Factor Zero - FF0

A fall factor zero (FF0) would be achieved if the climber could not fall any distance, such as when the rope or lanyard is anchored directly above them. This provides a good level of protection for the climber and the equipment, top-rope and bottom-rope climbing methods can provide minimal fall factors.

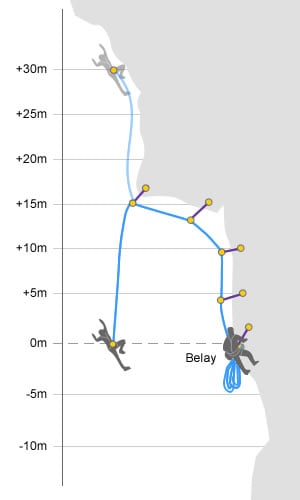

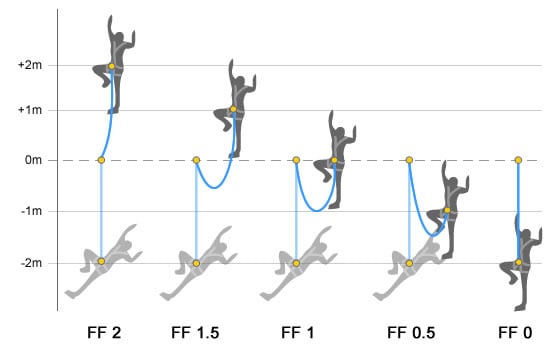

Fall Factors in Lead Climbing

The same principle is applied when lead climbing. The climber in the illustration has climbed 30m above the main belay and has placed running belays for protection during the ascent. The last piece of equipment that the climber placed was 15m above the main belay, the climber then climbs a further 15m but then falls off the route.

The climber falls a distance of 30m before the rope and the equipment are able to begin arresting the fall. Due to the overhanging section of the route there is 40m of rope between the climber and the belay device which results in a fall factor of 0.75.

Initially the climber fell 30m, also the rope stretches to absorb the energy and there maybe slippage through the belay device. Although the fall factor is quite low, the actual distance that the climber has fallen is quite significant.